Heavy-duty workbench plans in PDF format provide comprehensive guides for building sturdy, durable workbenches. These plans often include detailed instructions, shopping lists, and diagrams, making them ideal for both beginners and experienced woodworkers. They offer customizable designs to suit various workshop needs and preferences, ensuring a professional-grade workbench for heavy tasks and projects.

A heavy-duty workbench is an essential tool for any workshop, providing a sturdy surface for woodworking, repairs, and other projects. With the right plans, you can build a workbench tailored to your needs, ensuring durability and functionality. Heavy-duty workbench plans in PDF format offer a detailed guide, making it easier to construct a professional-grade workbench at home. These plans typically include step-by-step instructions, material lists, and diagrams to help you achieve a robust and long-lasting workbench.

Whether you’re a DIY enthusiast or a professional, having a reliable workbench is crucial for efficiency and safety. The plans often feature customizable designs, allowing you to adapt the size and features to your workspace and requirements. By following these plans, you can create a workbench that withstands heavy use and supports your projects with confidence. Start your project with a clear roadmap and enjoy the benefits of a well-crafted heavy-duty workbench.

Key Features of a Heavy Duty Workbench

A heavy-duty workbench is designed to withstand rigorous use, making it ideal for woodworking, metalworking, and other demanding tasks. One of its key features is a sturdy, reinforced frame, often constructed from thick lumber like 4x4s or 2x4s, ensuring stability and resistance to wobbling. The work surface is typically made from durable materials such as 3/4-inch plywood or solid wood, providing a smooth and resilient top. Many designs include lower shelves or cabinets for storage, keeping tools and supplies within easy reach.

Another important feature is the inclusion of stretchers or supports, which add structural integrity and prevent the workbench from sagging under heavy loads. Some plans also incorporate clamping systems, allowing for secure fastening of projects during assembly or repair. Additionally, mobility features like casters or adjustable legs can enhance versatility, enabling easy repositioning of the workbench in the workshop. These features combine to create a robust, functional, and adaptable workspace tailored for heavy-duty applications.

Benefits of Building a Heavy Duty Workbench

Building a heavy-duty workbench offers numerous benefits, particularly for woodworking enthusiasts, professionals, and DIYers. A sturdy workbench provides a reliable and stable surface for handling heavy tools, machinery, and materials, ensuring safety and precision in your work. It also enhances efficiency by keeping tools and supplies organized and within easy reach, saving time during projects.

Customization is another significant advantage. By building your own workbench, you can tailor its size, design, and features to meet your specific needs, whether it’s for woodworking, metalworking, or general repairs. This ensures the workbench fits seamlessly into your workshop setup. Additionally, a well-built workbench is a long-term investment, offering years of dependable service and potentially increasing the value of your workshop.

Overall, a heavy-duty workbench is more than just a piece of furniture—it’s a foundational tool that improves productivity, organization, and safety, making it an essential asset for any workshop.

Materials and Tools Required

Building a heavy-duty workbench requires sturdy materials like 4×4 lumber for legs, 2x4s for supports, and 3/4-inch plywood for the top. Essential tools include a saw, drill, impact driver, wrench, and clamps for secure assembly.

Lumber and Hardware Requirements

Constructing a heavy-duty workbench demands high-quality lumber and hardware to ensure durability and stability. For the frame, 4×4 lumber is ideal for legs and supports, while 2x4s can be used for additional bracing and stretchers. The workbench top typically requires 3/4-inch plywood or MDF for a smooth, sturdy surface. Hardware needs include galvanized or zinc-coated lag screws, carriage bolts, and washers to secure the frame tightly. Wood glue and wood filler are essential for reinforcing joints and creating a professional finish. Optional features like a lower shelf or vice installation may require additional materials, such as 2×2 lumber for shelf supports or a metal vice for added functionality. Always opt for pressure-treated lumber if the workbench will be exposed to moisture. Ensure all hardware is rated for heavy-duty use to withstand the demands of frequent and intense projects. Proper material selection is key to building a workbench that lasts for years.

Basic Tools Needed for Assembly

Assembling a heavy-duty workbench requires a set of essential tools to ensure accuracy and efficiency. A circular saw or hand saw is necessary for cutting lumber to precise measurements, while a drill press or cordless drill is needed for drilling pilot holes and driving screws. Sandpaper or a belt sander will help smooth out rough edges and surfaces. Clamps, such as F-style or bar clamps, are crucial for holding the frame and top in place during assembly. A tape measure and square are vital for ensuring all cuts and joints are accurate and aligned properly. Wrenches and sockets will come in handy for tightening bolts and lag screws securely. Additionally, a level ensures the workbench is perfectly aligned and stable. Having these basic tools on hand will streamline the assembly process and ensure a professional-grade result. Proper tool preparation is key to building a sturdy and reliable workbench for years of heavy use.

Safety Tips and Precautions

Always wear safety glasses, gloves, and a dust mask when cutting or drilling materials. Keep the workspace clean and well-lit to prevent accidents. Avoid loose clothing or jewelry that could get caught in tools. Ensure all tools are properly secured and follow manufacturer guidelines for safe operation. Maintain a stable work environment to avoid injuries and ensure a secure assembly process.

Essential Safety Measures

When building a heavy-duty workbench, prioritize safety to avoid accidents. Always wear protective gear such as safety glasses, gloves, and a dust mask to protect yourself from debris and airborne particles. Ensure the workspace is well-lit and clear of clutter to minimize tripping hazards. Secure all power tools and ensure they are in good working condition before use. Properly clamp or hold materials firmly to prevent movement during cutting or drilling. Avoid wearing loose clothing or jewelry that could get caught in tools. Maintain a stable work environment and avoid overreaching, as this can lead to loss of balance or tool control. Keep emergency equipment, such as a first aid kit and fire extinguisher, nearby. Follow all manufacturer guidelines for tools and materials, and never work while fatigued or distracted. By adhering to these essential safety measures, you can ensure a safe and successful workbench-building experience.

Common Mistakes to Avoid

Building a heavy-duty workbench requires attention to detail to ensure durability and functionality. One common mistake is using inadequate materials for the frame and top, which can result in a flimsy structure. Always use sturdy lumber and hardware suitable for heavy loads. Another mistake is improper alignment of the legs and supports, which can cause the workbench to wobble. Double-check all measurements and use clamps to ensure stability during assembly. Ignoring the importance of a level surface is another error, as an uneven workbench can hinder precision and safety. Additionally, rushing through the assembly process can lead to loose joints and structural weaknesses. It’s crucial to follow the plans meticulously and tighten all bolts and screws properly. Finally, neglecting to sand and finish the workbench can lead to splinters and wear over time. By avoiding these common pitfalls, you can construct a robust and reliable workbench tailored to your needs.

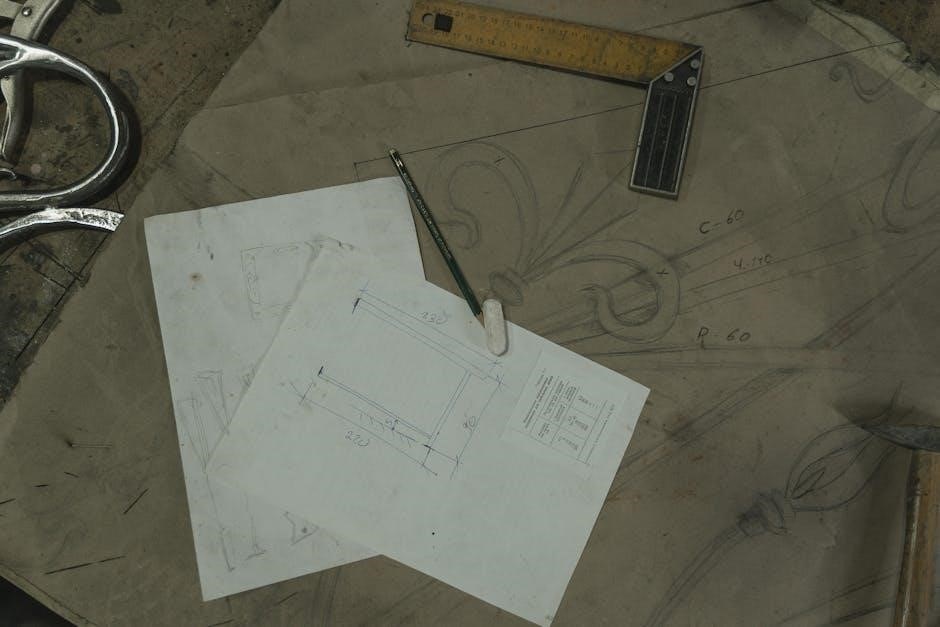

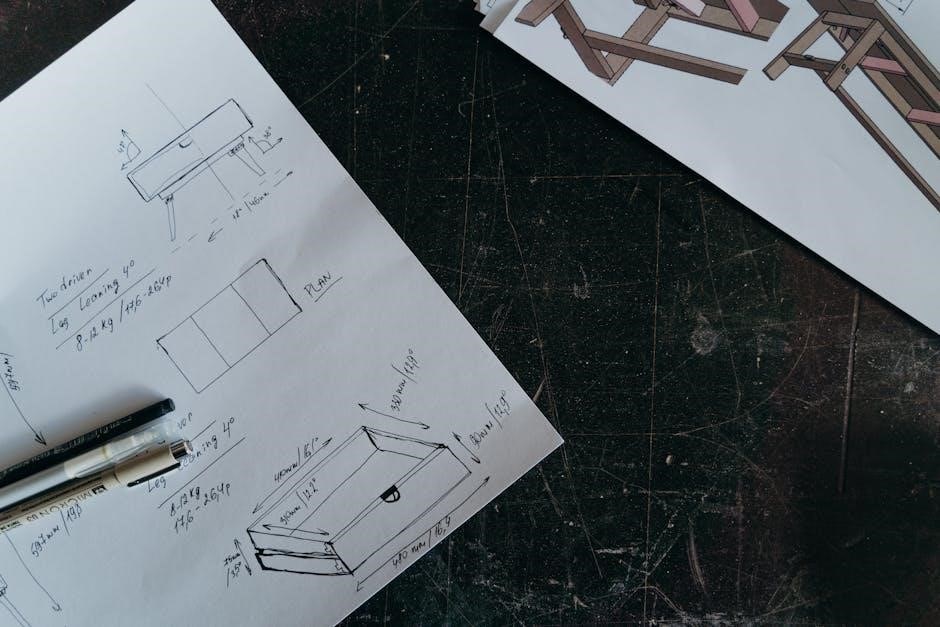

Step-by-Step Instructions

Heavy-duty workbench plans provide clear, step-by-step instructions for cutting, assembling, and finishing. Each phase is outlined with precision, ensuring ease of execution. From preparing components to final assembly, these guides help create a durable, professional-grade workbench.

Cutting and Preparing the Components

Cutting and preparing the components is the first critical step in building a heavy-duty workbench. Start by measuring and cutting the lumber according to the specified dimensions in your PDF plan. Use a circular saw or a miter saw for precise cuts. For the workbench legs, cut four pieces of 4×4 lumber to the desired height. Next, cut the frame rails and supports from 2×6 or 2×4 lumber, ensuring accuracy for a sturdy base. The workbench top, typically made from 3/4-inch plywood, should be cut to the planned size using a circular saw or jigsaw. Sand all cut edges to smooth them out and remove splinters. Pre-drill holes for screws and bolts to avoid splitting the wood. Organize and label each component for easy assembly later. Use clamps to hold pieces steady during cutting and drilling. Proper preparation ensures a seamless assembly process and a professional finish. Always wear safety goggles and a dust mask when cutting and sanding materials.

Assembling the Workbench Frame

Assembling the workbench frame begins with attaching the legs to the frame rails. Use heavy-duty brackets or screws to secure the legs, ensuring a sturdy base. Next, attach the side and rear rails to the legs, forming a rectangular frame. Use clamps to hold the pieces in place while tightening the bolts or screws; Ensure all corners are square by measuring the diagonals. Once the frame is assembled, add the lower shelf supports and stretchers for additional stability. These stretchers help prevent the frame from racking under heavy loads. Attach the bottom shelf slats or plywood to the supports for storage. Use a level to confirm the frame is even and plumb. Tighten all bolts firmly to ensure rigidity. The frame should be robust enough to support heavy tools and materials. Proper alignment and secure fastening are critical at this stage to ensure the workbench withstands demanding tasks. Double-check all connections before moving on to the next step.

Final Assembly and Testing

Once the frame and top are prepared, begin the final assembly by attaching the workbench top to the frame using heavy-duty screws or bolts. Ensure the top is evenly aligned and securely fastened. Use clamps to hold the top in place while tightening the fasteners. Next, install any additional features, such as a vise or storage drawers, according to your plan. Double-check all connections to ensure they are tight and sturdy. Finally, test the workbench by applying weight and checking for stability. Ensure the surface is level and free of wobble. Sand any rough edges or surfaces for a smooth finish. Perform a safety inspection to confirm all components are securely attached and the workbench can withstand heavy use. Once satisfied, your heavy-duty workbench is ready for woodworking, repairs, or other demanding tasks. Proper assembly and testing ensure long-term durability and reliability for your workshop needs.